Rail-Inspector® Overview

Use Cases

Rail-Inspector® Features

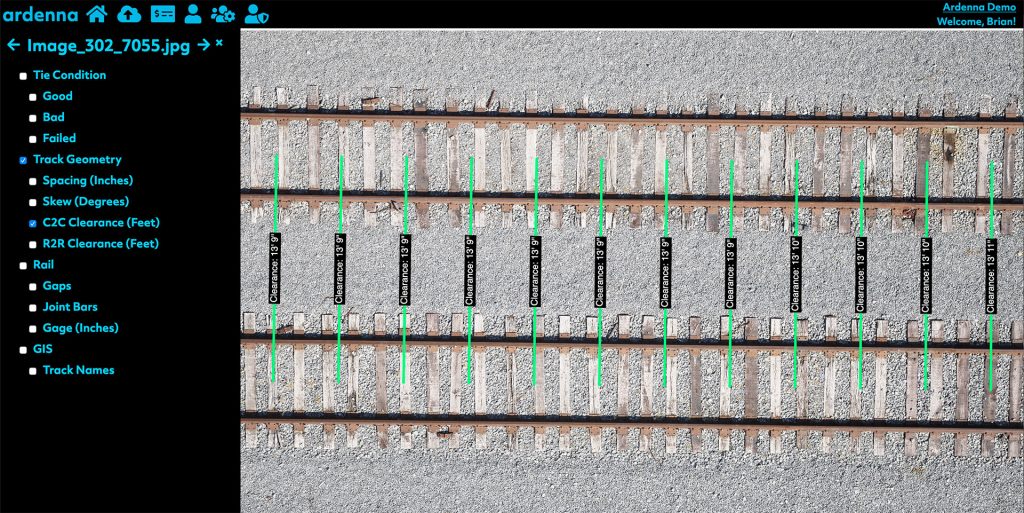

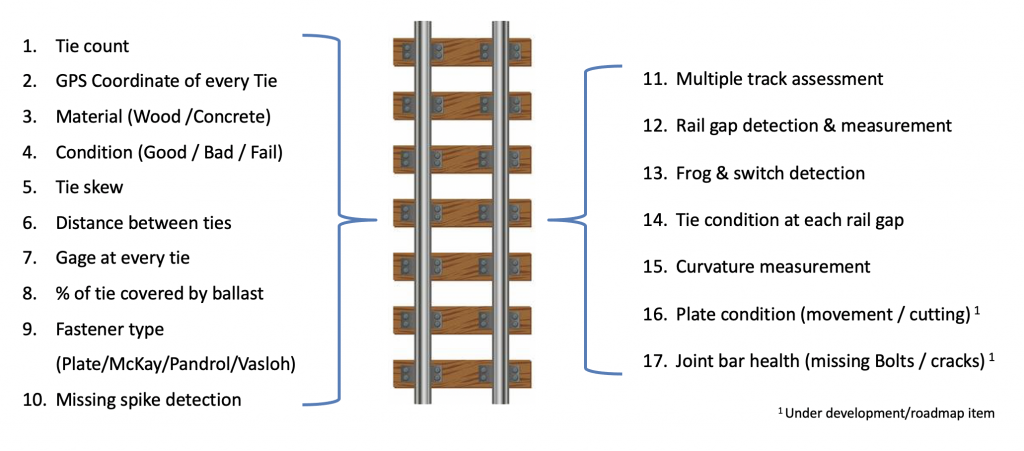

Rail-Inspector uses advanced machine-learning algorithms to automatically and accurately process and analyze visual data captured during aerial surveys, identifying and measuring railway features, classifying anomalies and assessing the health of track and railbed infrastructure.

(click the tabs on the left sidebar to view sample detections)

- Tie Condition

- Tie Skew

- Tie Spacing

- Track Clearance

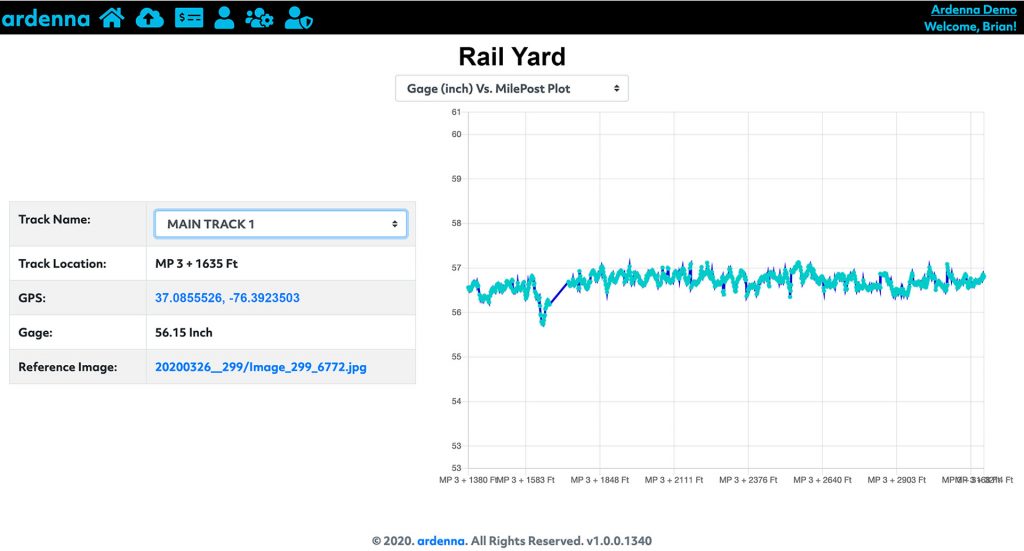

- Gage Measurement

- Fastener Identification

- Rail Gap Measurement

- Joint Bar Detection

- High-Resolution Imagery

- (and more)

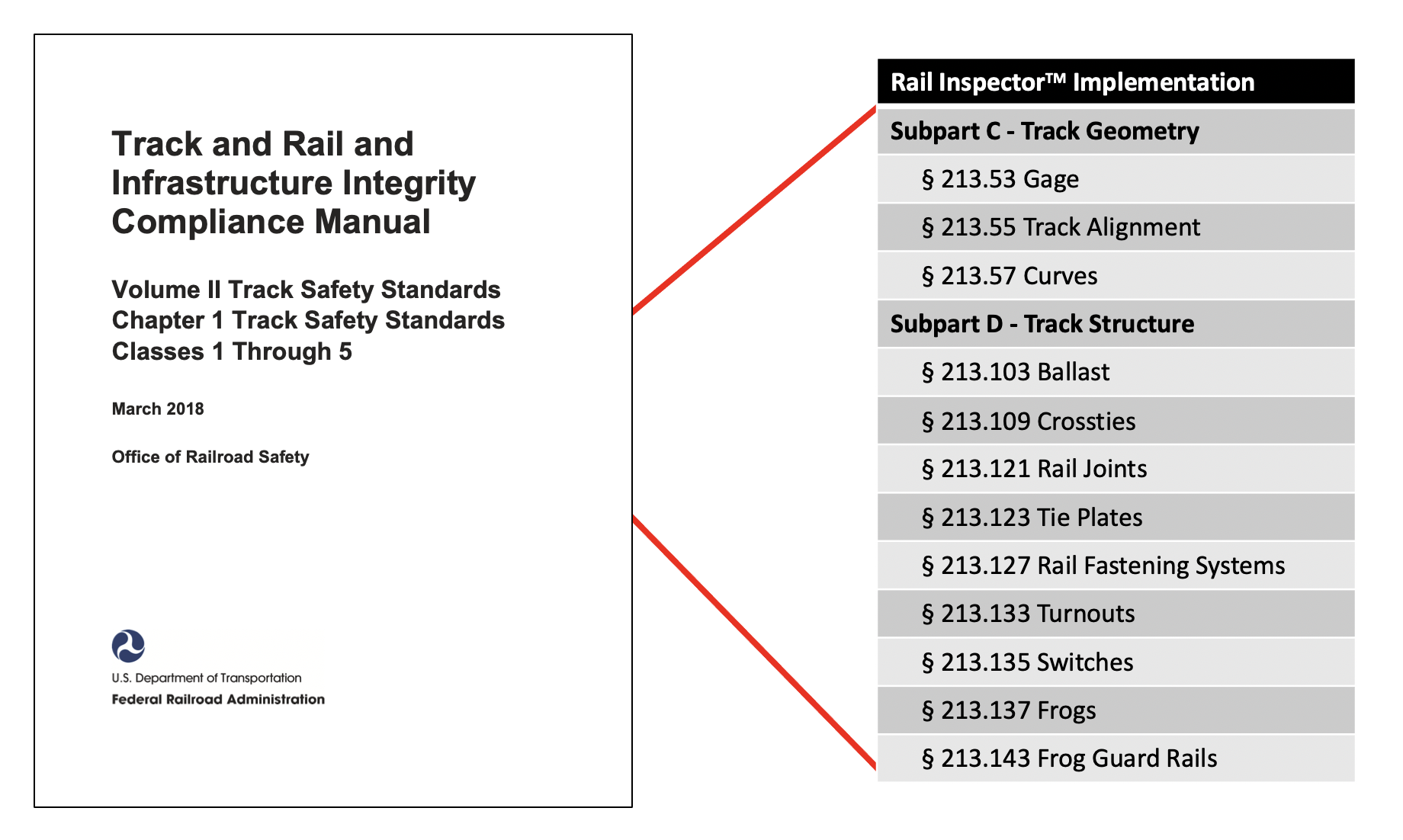

FRA Compliance

Rail-Inspector helps track owners comply with the Federal Railroad Administration (FRA) Track Safety Standards (TSS) by generating data related to Track Geometry and Track Structure.

With data generated at every crosstie, Rail-Inspector provides a comprehensive dataset that gives insight into the health of the track and railbed.

Benefits

Rail-Inspector excels at providing track owners with more insight into their track inspection and maintenance activities to enable data-driven decisions that reduce costs and improve worker and operational safety.

Worker & OpS Safety

Operational Efficiencies

Digital

Record

Comprehensive Dataset

Track Health Assessment

Comprehensive

Rail-Inspector® provides a comprehensive digital record of track condition data. The diagram below illustrates the wide array of detections that Rail-Inspector analyzes and reports.

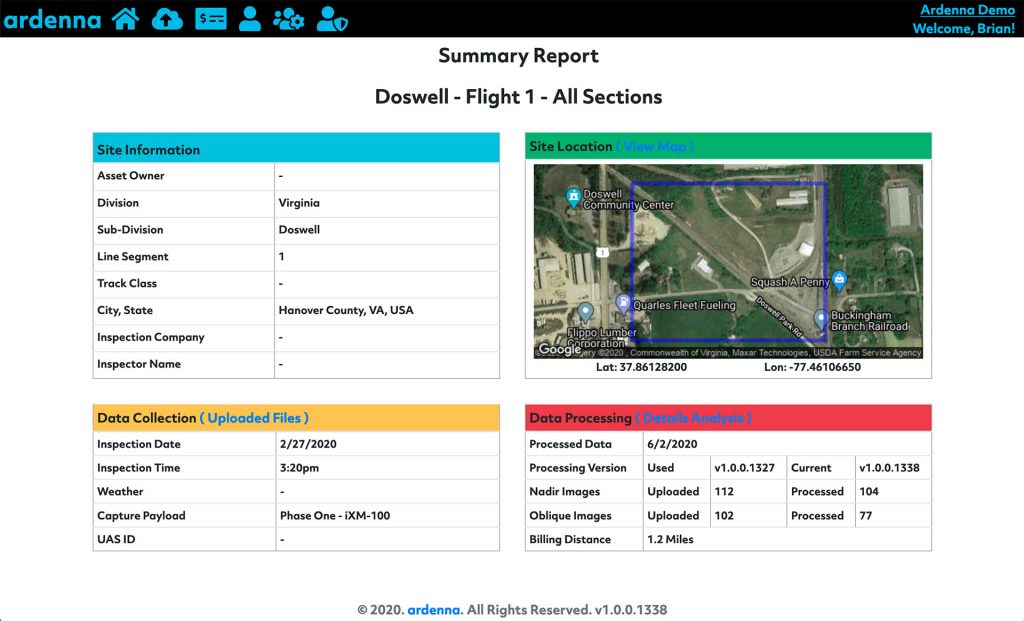

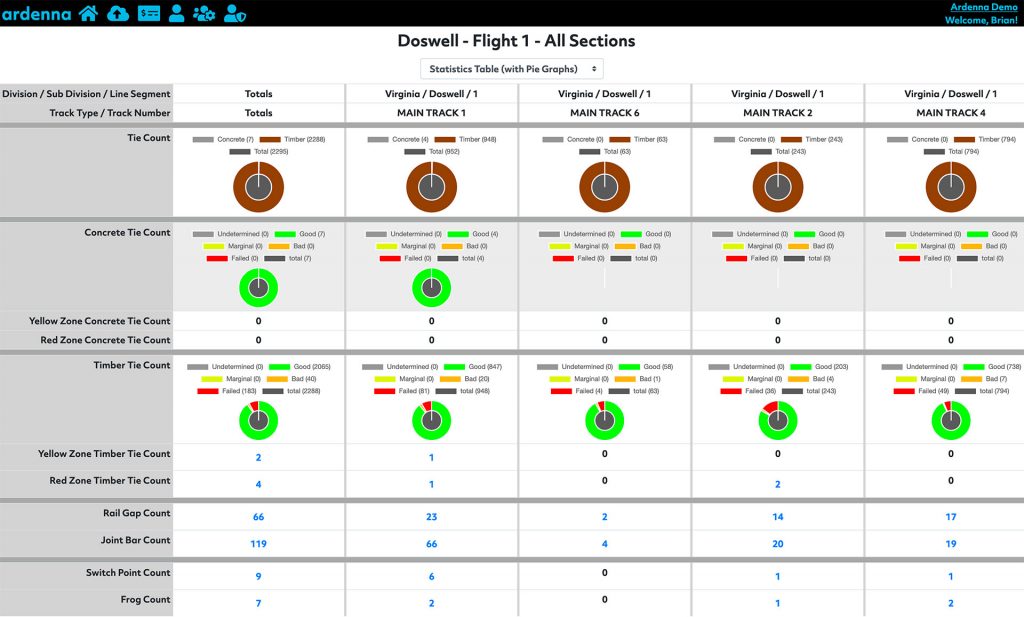

Results Visualizations

Rail-Inspector® results are available 24/7 through the Rail-Inspector web portal where stakeholders can interactively review results through annotated map and image visualizations, data plots, and detailed reports.

Map

View

Summary

View

Detailed

ViEW

Plot

View